www.continual.com.tr

Truck

Bus

Heavy Duty

Brake

Caliper Repair System

Contact Information

--

--

--

Best Regards

International Sales and Customer Relations

Mob=+ 90 530 320 60 22

E-Mail : export@continual.com.tr

Continual Brake Caliper Systems

www.continual.com.tr

HMF Plastik. Tesktil. İnş. Gıda San. Tic. Ltd. Şti.

Phone :+90-212 671 68 23

Fax :+90-212 671 68 30

skype: continualsales

Showroom Address =

İkitelli Organize Sanayi Bölgesi Dolapdere Sanayi Sitesi 2.ada No: 2 İKİTELLİ-BAŞAKŞEHİR / İSTANBUL / TURKEY

Factory Address =

Fevzi Çakmak Mahallesi Büsan Ozel Organize Sanayi Sitesi 10664 Sokak No:31/D Karatay/KONYA/TURKEY

Please Contact Us

Haszonjárművek Truck Bus Féknyereg Repair készletek és rendszerek

Veículos Comerciais Truck Bus Caliper Kits de reparação e Sistemas

Vehículos Comerciales Camiones Bus Caliper Kits y sistemas de reparación

Kommersiële Voertuie Truck Bus caliper herstel kits en stelsels

Commercial Vehicles Truck Bus Caliper Kits Riparimi Dhe Systems

المركبات التجارية، و الشاحنات والحافلات ، الفرامل ، إصلاح الفرجار ، مجموعات، مجموعة والأنظمة

Կոմերցիոն Տրանսպորտ , բեռնատար, ավտոբուս , արգելակ , Caliper վերանորոգում , որոնում , Սահմանել եւ համակարգեր

Ticarət Avtomobil , Yük maşınları , Avtobus , Əyləc, Caliper təmiri , Kitleri , Set və sistemləri

Ibilgailuen Merkataritza , Kamioi , Bus, balazta , Caliper Konponketa, Jantziak, Set Eta Systems

Камерцыйны транспарт , грузавік , аўтобус , тормаз , суппорт , рамонт , наборы , набор і сістэмы

Kamiercyjny transpart , hruzavik , aŭtobus , tormaz , support , ramont , nabory , nabor i sistemy

Komercijalnih vozila , kamiona , autobusa , pri kočenju , mjerač popravak , kompleti , Set i sisteme

Тежкотоварни автомобили , камиони, автобуси , Спирачни , шублер ремонт, комплекти , сет и Системи

Tezhkotovarni avtomobili , kamioni, avtobusi , Spirachni , shubler remont, komplekti , set i Sistemi

Vehicles Comercials , Camions , Autobusos , Fre , Reparació Calibre , Kits , SET i Sistemes

Gospodarska vozila , kamione , autobusa , kočnica , Debljina popravak , Setovi , postaviti i sustavi

Užitková vozidla , nákladní vozidla, autobusy , čelisti , Caliper Opravy , Stavebnice , nastavení a systémy

Erhvervskøretøjer, lastbiler, busser , Brake , Caliper Reparation , Kits , sæt og Systems

Feithiclí Tráchtála , Truck , Bus , Coscáin , Deisiúchán Caliper , trealamh , Set agus Córais

Veicoli Commerciali , camion , autobus , freno , compasso riparazione , Kit , SET e Sistemi

Commercial Vehicles , lastbilar, bussar , Brake , Caliper Reparation , Kit , set och Systems

Комерційний транспорт , вантажівка, автобус, гальмо , супорт , ремонт , набори , набір та системи

Vehículos Comerciales, Camiones , Autobuses , Freno , Reparación Calibre, Kits , SET y Sistemas

Pojazdy Użytkowe , ciężarowych, autobusów , hamulcowe , Zacisk naprawcze, zestawy , Set i systemów

Ticari Araçlar , Kamyon , Otobüs , Fren , Kaliper Tamir , Takımları , Set ve Sistemleri

Veículos comerciais, caminhões, ônibus , freio, reparação Caliper, Kits , SET e Sistemas

Nyttekjøretøy, lastebil, buss , Brake, Sylinder Reparasjon , Kits , Set og systemer

Gospodarska vozila , tovorna vozila , avtobuse , zavore , zavorne čeljusti popravila , kompleti , Set in sistemi

وسایل نقلیه تجاری ، کامیون، اتوبوس، ترمز ، تعمیر کولیس ، کیت، مجموعه و سیستم

Véhicules utilitaires , de camions , d'autobus , de frein , étrier réparation , Kits , SET et Systèmes

Úžitkové vozidlá , nákladné vozidlá , autobusy , čeľuste , Caliper Opravy , Stavebnice , nastavenie a systémy

კომერციული მანქანები , სატვირთო, ავტობუსი, Brake, Caliper რემონტი, ფორმები , Set და სისტემები

Nutzfahrzeuge, LKW , Bus, Bremsen , Bremssattel Reparatur , Kits, Set und Systeme

Komercinės transporto priemonės , sunkvežimių, autobusų , Stabdžių , apkaba remontas, Rinkiniai , Nustatyti ir sistemos

Commercial Vehicles , kravas automašīnu, autobusu , bremžu , suports remonts , Komplekti , iestatīt un sistēmas

Commercial Vehicles , veoauto, buss , piduriklotsid , Pidurisadula remont, Kits, Set ja süsteemid

Caminhões e ônibus Caliper Kits de reparação , sistema,

Kamiona i autobusa na kočnicama popravak setove, sustav ,

Kuorma- ja linja- Jarrusatula korjaussarjat järjestelmä ,

Truck en Bus Remklauw reparatiesets , systeem ,

Camions et bus Étrier de frein Kits de réparation , le système

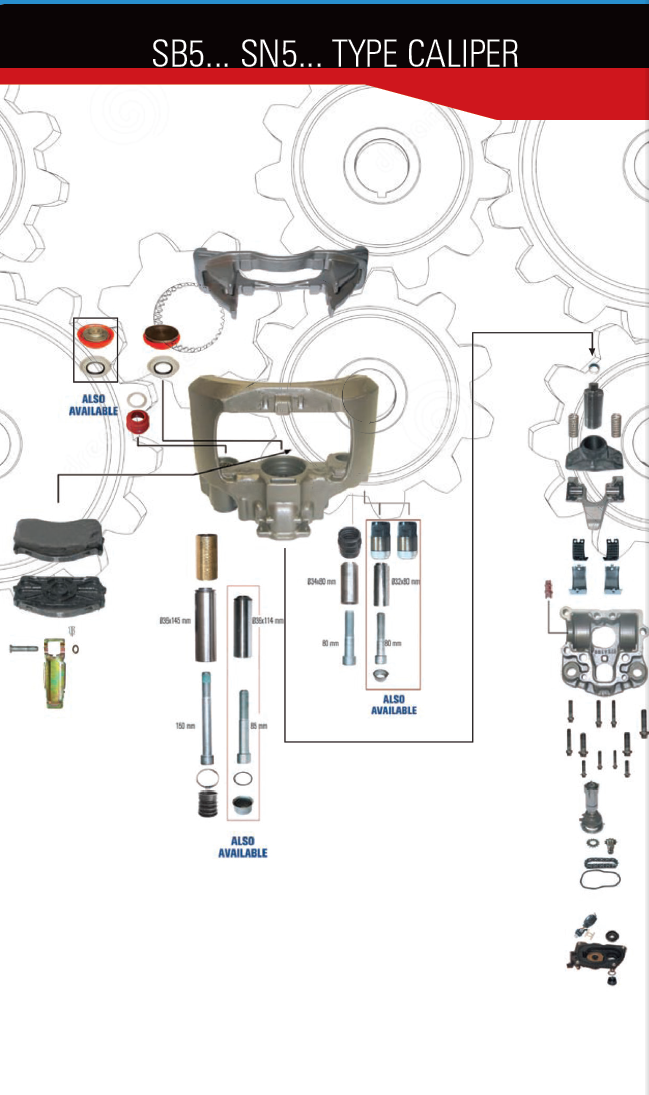

Calipers

The brake caliper is the assembly which houses the brake pads and pistons. The pistons are usually made of plastic, aluminium or chrome-plated steel.

Calipers are of two types, floating or fixed. A fixed caliper does not move relative to the disc and is thus less tolerant of disc imperfections. It uses one or more pairs of opposing pistons to clamp from each side of the disc, and is more complex and expensive than a floating caliper.

A floating caliper (also called a "sliding caliper") moves with respect to the disc, along a line parallel to the axis of rotation of the disc; a piston on one side of the disc pushes the inner brake pad until it makes contact with the braking surface, then pulls the caliper body with the outer brake pad so pressure is applied to both sides of the disc. Floating caliper (single piston) designs are subject to sticking failure, caused by dirt or corrosion entering at least one mounting mechanism and stopping its normal movement. This can lead to the caliper's pads rubbing on the disc when the brake is not engaged or engaging it at an angle. Sticking can result from infrequent vehicle use, failure of a seal or rubber protection boot allowing debris entry, dry-out of the grease in the mounting mechanism and subsequent moisture incursion leading to corrosion, or some combination of these factors. Consequences may include reduced fuel efficiency, extreme heating of the disc or excessive wear on the affected pad. A sticking front caliper may also cause steering vibration.

An air brake or, more formally, a compressed air brake system, is a type of friction brake for vehicles in which compressed airpressing on a piston is used to apply the pressure to the brake pad needed to stop the vehicle. Air brakes are used in large heavy vehicles, particularly those having multiple trailers which must be linked into the brake system, such as trucks, buses, trailers, andsemi-trailers in addition to their use in railroad trains. George Westinghouse first developed air brakes for use in railway service. He patented a safer air brake on March 5, 1872. Westinghouse made numerous alterations to improve his air pressured brake invention, which led to various forms of the automatic brake. In the early 20th century, after its advantages were proven in railway use, it was adopted by manufacturers of trucks and heavy road vehicles.

Design and function

Air brake systems are typically used on heavy trucks and buses. The system consists of service brakes, parking brakes, a control pedal, and an air storage tank. For the parking brake, there is a disc or drum brake arrangement which is designed to be held in the 'applied' position by spring pressure. Air pressure must be produced to release these "spring brake" parking brakes. For the service brakes (the ones used while driving for slowing or stopping) to be applied, the brake pedal is pushed, routing the air under pressure (approx 100–120 psi or 690–830 kPa) to the brake chamber, causing the brake to be engaged. Most types of truck air brakes are drum brakes, though there is an increasing trend towards the use of disc brakes in this application. The air compressor draws filtered air from the atmosphere and forces it into high-pressure reservoirs at around 120 psi (830 kPa). Most heavy vehicles have a gauge within the driver's view, indicating the availability of air pressure for safe vehicle operation, often including warning tones or lights. Setting of the parking/emergency brake releases the pressurized air in the lines between the compressed air storage tank and the brakes, thus allowing the spring actuated parking brake to engage. A sudden loss of air pressure would result in full spring brake pressure immediately.

A compressed air brake system is divided into a supply system and a control system. The supply system compresses, stores and supplies high-pressure air to the control system as well as to additional air operated auxiliary truck systems (gearbox shift control, clutch pedal air assistance servo, etc.).

Supply system

Highly simplified air brake diagram on a commercial road vehicle (does not show all air reservoirs and all applicable air valves).

The air compressor is driven by the engine either by crankshaft pulley via a belt or directly from the engine timing gears. It is lubricated and cooled by the engine lubrication and cooling systems. Compressed air is first routed through a cooling coil and into an air dryer which removes moisture and oil impurities and also may include a pressure regulator, safety valve and smaller purge reservoir. As an alternative to the air dryer, the supply system can be equipped with an anti-freeze device and oil separator. The compressed air is then stored in a reservoir (also called a wet tank) from which it is then distributed via a four way protection valve into the front and rear brake circuit air reservoir, a parking brake reservoir and an auxiliary air supply distribution point. The system also includes various check, pressure limiting, drain and safety valves.

Air brake systems may include a wig wag device which deploys to warn the driver if the system air pressure drops too low.

Control system

The control system is further divided into two service brake circuits: the parking brake circuit and the trailer brake circuit. This dual brake circuit is further split into front and rear wheel circuits which receive compressed air from their individual reservoirs for added safety in case of an air leak. The service brakes are applied by means of a brake pedal air valve which regulates both circuits. The parking brake is the air operated spring brake type where its applied by spring force in the spring brake cylinder and released by compressed air via hand control valve. The trailer brake consists of a direct two line system: the supply line (marked red) and the separate control or service line (marked blue). The supply line receives air from the prime mover park brake air tank via a park brake relay valve and the control line is regulated via the trailer brake relay valve. The operating signals for the relay are provided by the prime mover brake pedal air valve, trailer service brake hand control (subject to a country's relevant heavy vehicle legislation) and the prime mover park brake hand control.

Park brake valve

Spring brake cylinder

Air brake foot valve

Trailer brake relay valve

Truck air compressor

Air dryer

Air brake relay valve

Four way protection valve

Advantages

Air brakes are used as an alternative to hydraulic brakes which are used on lighter vehicles such as automobiles. Hydraulic brakes use a liquid (hydraulic fluid) to transfer pressure from the brake pedal to the brake shoe to stop the vehicle. Air brakes have several advantages for large multitrailer vehicles:

The supply of air is unlimited, so the brake system can never run out of its operating fluid, as hydraulic brakes can. Minor leaks do not result in brake failures.

Air line couplings are easier to attach and detach than hydraulic lines; there is no danger of letting air into a pneumatic circuit. So air brake circuits of trailers can be attached and removed easily by operators with little training.

Air not only serves as a fluid for transmission of force, but also stores potential energy. So it can serve to control the force applied. Air brake systems include an air tank that stores sufficient energy to stop the vehicle if the compressor fails.

Air brakes are effective even with considerable leakage, so an air brake system can be designed with sufficient "fail-safe" capacity to stop the vehicle safely even when leaking.

Driving technique and operator licensing

As air brakes must be operated differently from more common hydraulic systems, most countries require additional training and licensing in order to legally drive any vehicle using an air brake

Driving a vehicle with air brakes requires basic knowledge of proper maintenance as well. A driver is required to inspect the air pressurization system prior to driving and make sure all tanks are in working order. In addition, the manner of applying brakes is usually different from regular hydraulic type systems. Pressure is applied slowly and air levels must be monitored at all times as a loss in air pressure will result in brake lockup aka "dynamiting". Unlike hydraulic brakes, air brakes must not be pumped repeatedly as the repetitive application and release of air will drain the system prematurely.

Best Regards

İnternational Sales and Customer Relations

Mob=+ 90 530 320 60 22

E-Mail : export@continual.com.tr

Continual Brake Caliper Systems

Haszonjárművek Truck Bus Féknyereg Repair készletek és rendszerek

Veículos Comerciais Truck Bus Caliper Kits de reparação e Sistemas

Vehículos Comerciales Camiones Bus Caliper Kits y sistemas de reparación

Kommersiële Voertuie Truck Bus caliper herstel kits en stelsels

Commercial Vehicles Truck Bus Caliper Kits Riparimi Dhe Systems

المركبات التجارية، و الشاحنات والحافلات ، الفرامل ، إصلاح الفرجار ، مجموعات، مجموعة والأنظمة

Կոմերցիոն Տրանսպորտ , բեռնատար, ավտոբուս , արգելակ , Caliper վերանորոգում , որոնում , Սահմանել եւ համակարգեր

Ticarət Avtomobil , Yük maşınları , Avtobus , Əyləc, Caliper təmiri , Kitleri , Set və sistemləri

Ibilgailuen Merkataritza , Kamioi , Bus, balazta , Caliper Konponketa, Jantziak, Set Eta Systems

Камерцыйны транспарт , грузавік , аўтобус , тормаз , суппорт , рамонт , наборы , набор і сістэмы

Kamiercyjny transpart , hruzavik , aŭtobus , tormaz , support , ramont , nabory , nabor i sistemy

Komercijalnih vozila , kamiona , autobusa , pri kočenju , mjerač popravak , kompleti , Set i sisteme

Тежкотоварни автомобили , камиони, автобуси , Спирачни , шублер ремонт, комплекти , сет и Системи

Tezhkotovarni avtomobili , kamioni, avtobusi , Spirachni , shubler remont, komplekti , set i Sistemi

Vehicles Comercials , Camions , Autobusos , Fre , Reparació Calibre , Kits , SET i Sistemes

Gospodarska vozila , kamione , autobusa , kočnica , Debljina popravak , Setovi , postaviti i sustavi

Užitková vozidla , nákladní vozidla, autobusy , čelisti , Caliper Opravy , Stavebnice , nastavení a systémy

Erhvervskøretøjer, lastbiler, busser , Brake , Caliper Reparation , Kits , sæt og Systems

Feithiclí Tráchtála , Truck , Bus , Coscáin , Deisiúchán Caliper , trealamh , Set agus Córais

Veicoli Commerciali , camion , autobus , freno , compasso riparazione , Kit , SET e Sistemi

Commercial Vehicles , lastbilar, bussar , Brake , Caliper Reparation , Kit , set och Systems

Комерційний транспорт , вантажівка, автобус, гальмо , супорт , ремонт , набори , набір та системи

Vehículos Comerciales, Camiones , Autobuses , Freno , Reparación Calibre, Kits , SET y Sistemas

Pojazdy Użytkowe , ciężarowych, autobusów , hamulcowe , Zacisk naprawcze, zestawy , Set i systemów

Ticari Araçlar , Kamyon , Otobüs , Fren , Kaliper Tamir , Takımları , Set ve Sistemleri

Veículos comerciais, caminhões, ônibus , freio, reparação Caliper, Kits , SET e Sistemas

Nyttekjøretøy, lastebil, buss , Brake, Sylinder Reparasjon , Kits , Set og systemer

Gospodarska vozila , tovorna vozila , avtobuse , zavore , zavorne čeljusti popravila , kompleti , Set in sistemi

وسایل نقلیه تجاری ، کامیون، اتوبوس، ترمز ، تعمیر کولیس ، کیت، مجموعه و سیستم

Véhicules utilitaires , de camions , d'autobus , de frein , étrier réparation , Kits , SET et Systèmes

Úžitkové vozidlá , nákladné vozidlá , autobusy , čeľuste , Caliper Opravy , Stavebnice , nastavenie a systémy

კომერციული მანქანები , სატვირთო, ავტობუსი, Brake, Caliper რემონტი, ფორმები , Set და სისტემები

Nutzfahrzeuge, LKW , Bus, Bremsen , Bremssattel Reparatur , Kits, Set und Systeme

Komercinės transporto priemonės , sunkvežimių, autobusų , Stabdžių , apkaba remontas, Rinkiniai , Nustatyti ir sistemos

Commercial Vehicles , kravas automašīnu, autobusu , bremžu , suports remonts , Komplekti , iestatīt un sistēmas

Commercial Vehicles , veoauto, buss , piduriklotsid , Pidurisadula remont, Kits, Set ja süsteemid

Caminhões e ônibus Caliper Kits de reparação , sistema,

Kamiona i autobusa na kočnicama popravak setove, sustav ,

Kuorma- ja linja- Jarrusatula korjaussarjat järjestelmä ,

Truck en Bus Remklauw reparatiesets , systeem ,

Camions et bus Étrier de frein Kits de réparation , le système

Calipers

The brake caliper is the assembly which houses the brake pads and pistons. The pistons are usually made of plastic, aluminium or chrome-plated steel.

Calipers are of two types, floating or fixed. A fixed caliper does not move relative to the disc and is thus less tolerant of disc imperfections. It uses one or more pairs of opposing pistons to clamp from each side of the disc, and is more complex and expensive than a floating caliper.

A floating caliper (also called a "sliding caliper") moves with respect to the disc, along a line parallel to the axis of rotation of the disc; a piston on one side of the disc pushes the inner brake pad until it makes contact with the braking surface, then pulls the caliper body with the outer brake pad so pressure is applied to both sides of the disc. Floating caliper (single piston) designs are subject to sticking failure, caused by dirt or corrosion entering at least one mounting mechanism and stopping its normal movement. This can lead to the caliper's pads rubbing on the disc when the brake is not engaged or engaging it at an angle. Sticking can result from infrequent vehicle use, failure of a seal or rubber protection boot allowing debris entry, dry-out of the grease in the mounting mechanism and subsequent moisture incursion leading to corrosion, or some combination of these factors. Consequences may include reduced fuel efficiency, extreme heating of the disc or excessive wear on the affected pad. A sticking front caliper may also cause steering vibration.

An air brake or, more formally, a compressed air brake system, is a type of friction brake for vehicles in which compressed airpressing on a piston is used to apply the pressure to the brake pad needed to stop the vehicle. Air brakes are used in large heavy vehicles, particularly those having multiple trailers which must be linked into the brake system, such as trucks, buses, trailers, andsemi-trailers in addition to their use in railroad trains. George Westinghouse first developed air brakes for use in railway service. He patented a safer air brake on March 5, 1872. Westinghouse made numerous alterations to improve his air pressured brake invention, which led to various forms of the automatic brake. In the early 20th century, after its advantages were proven in railway use, it was adopted by manufacturers of trucks and heavy road vehicles.

Design and function

Air brake systems are typically used on heavy trucks and buses. The system consists of service brakes, parking brakes, a control pedal, and an air storage tank. For the parking brake, there is a disc or drum brake arrangement which is designed to be held in the 'applied' position by spring pressure. Air pressure must be produced to release these "spring brake" parking brakes. For the service brakes (the ones used while driving for slowing or stopping) to be applied, the brake pedal is pushed, routing the air under pressure (approx 100–120 psi or 690–830 kPa) to the brake chamber, causing the brake to be engaged. Most types of truck air brakes are drum brakes, though there is an increasing trend towards the use of disc brakes in this application. The air compressor draws filtered air from the atmosphere and forces it into high-pressure reservoirs at around 120 psi (830 kPa). Most heavy vehicles have a gauge within the driver's view, indicating the availability of air pressure for safe vehicle operation, often including warning tones or lights. Setting of the parking/emergency brake releases the pressurized air in the lines between the compressed air storage tank and the brakes, thus allowing the spring actuated parking brake to engage. A sudden loss of air pressure would result in full spring brake pressure immediately.

A compressed air brake system is divided into a supply system and a control system. The supply system compresses, stores and supplies high-pressure air to the control system as well as to additional air operated auxiliary truck systems (gearbox shift control, clutch pedal air assistance servo, etc.).

Supply system

Highly simplified air brake diagram on a commercial road vehicle (does not show all air reservoirs and all applicable air valves).

The air compressor is driven by the engine either by crankshaft pulley via a belt or directly from the engine timing gears. It is lubricated and cooled by the engine lubrication and cooling systems. Compressed air is first routed through a cooling coil and into an air dryer which removes moisture and oil impurities and also may include a pressure regulator, safety valve and smaller purge reservoir. As an alternative to the air dryer, the supply system can be equipped with an anti-freeze device and oil separator. The compressed air is then stored in a reservoir (also called a wet tank) from which it is then distributed via a four way protection valve into the front and rear brake circuit air reservoir, a parking brake reservoir and an auxiliary air supply distribution point. The system also includes various check, pressure limiting, drain and safety valves.

Air brake systems may include a wig wag device which deploys to warn the driver if the system air pressure drops too low.

Control system

The control system is further divided into two service brake circuits: the parking brake circuit and the trailer brake circuit. This dual brake circuit is further split into front and rear wheel circuits which receive compressed air from their individual reservoirs for added safety in case of an air leak. The service brakes are applied by means of a brake pedal air valve which regulates both circuits. The parking brake is the air operated spring brake type where its applied by spring force in the spring brake cylinder and released by compressed air via hand control valve. The trailer brake consists of a direct two line system: the supply line (marked red) and the separate control or service line (marked blue). The supply line receives air from the prime mover park brake air tank via a park brake relay valve and the control line is regulated via the trailer brake relay valve. The operating signals for the relay are provided by the prime mover brake pedal air valve, trailer service brake hand control (subject to a country's relevant heavy vehicle legislation) and the prime mover park brake hand control.

Park brake valve

Spring brake cylinder

Air brake foot valve

Trailer brake relay valve

Truck air compressor

Air dryer

Air brake relay valve

Four way protection valve

Advantages

Air brakes are used as an alternative to hydraulic brakes which are used on lighter vehicles such as automobiles. Hydraulic brakes use a liquid (hydraulic fluid) to transfer pressure from the brake pedal to the brake shoe to stop the vehicle. Air brakes have several advantages for large multitrailer vehicles:

The supply of air is unlimited, so the brake system can never run out of its operating fluid, as hydraulic brakes can. Minor leaks do not result in brake failures.

Air line couplings are easier to attach and detach than hydraulic lines; there is no danger of letting air into a pneumatic circuit. So air brake circuits of trailers can be attached and removed easily by operators with little training.

Air not only serves as a fluid for transmission of force, but also stores potential energy. So it can serve to control the force applied. Air brake systems include an air tank that stores sufficient energy to stop the vehicle if the compressor fails.

Air brakes are effective even with considerable leakage, so an air brake system can be designed with sufficient "fail-safe" capacity to stop the vehicle safely even when leaking.

Driving technique and operator licensing

As air brakes must be operated differently from more common hydraulic systems, most countries require additional training and licensing in order to legally drive any vehicle using an air brake

Driving a vehicle with air brakes requires basic knowledge of proper maintenance as well. A driver is required to inspect the air pressurization system prior to driving and make sure all tanks are in working order. In addition, the manner of applying brakes is usually different from regular hydraulic type systems. Pressure is applied slowly and air levels must be monitored at all times as a loss in air pressure will result in brake lockup aka "dynamiting". Unlike hydraulic brakes, air brakes must not be pumped repeatedly as the repetitive application and release of air will drain the system prematurely.

Best Regards

İnternational Sales and Customer Relations

Mob=+ 90 530 320 60 22

E-Mail : export@continual.com.tr

Continual Brake Caliper Systems